Electromagnetic Interference (EMI) compliance testing

Measuring emissions in accordance with standards

Unintended electromagnetic field generation from a device, resulting in electromagnetic interference (EMI) can have many sources; the reason for EMI testing is to ensure that any fields arising from a device will not interfere in the correct function of other devices.

Assessing EMI as part of EMC conformance test, confirms that the emissions are in accordance with the standards and norms that apply to the product and region. For details of the standards applying per region and product type, see the detailed EMC standards.

EMC compliance test setup

An EMC compliance test setup must ensure repeatability. The environment is free of ambient noise and without reflecting surfaces. This is achieved by anechoic rooms that are shielded against outside noise as well as equipped with absorbing material to reduce reflections within the room. As an alternative, measurements can be performed outside at an empty and remote location. The so-called open area test site (OATS) forms the blueprint of a test site, which only reflects electromagnetic waves on the ground plane. Semi anechoic chambers imitate those inside, with the advantage of a better shielding against ambient noise. Nowadays more and more fully anechoic rooms (FAR) are being used, featuring absorbing floors. They deduct the need for a time-consuming height scan that eliminates the effect of floor reflections in SAC’s. EMS tests reach transmit powers in kilowatt regions so that they must be performed in a fully enclosed room. An open area test site is not applicable.

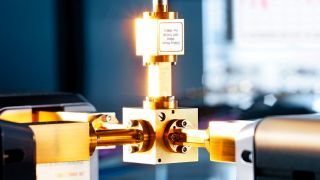

Compliance tests use large antennas with high gain and high maximum transmit power. While the latter one is important for EMS testing, EMI demands best sensitivity. A high bandwidth ensures that fewer antenna changes slow down the testing process. The antenna points onto the device under test (DUT), meters apart in the far field. The DUT typically rests on a table of a dielectric material and gets rotated, to capture all angles of potential emissions. For conducted testing, artificial networks (AN) decouple the emissions on power or signal lines and transfer them to the test receiver.

EMC compliance test equipment from Rohde & Schwarz for the measurement of radiated and conducted emissions

Rohde & Schwarz can supply all the measurement instruments, supporting system components, software, antennas, line impedance stabilization networks (LISN) and additional equipment required to measure both radiated and conducted interference. All the individual components are fully compatible with each other; R&S EMC compliance systems are integrated from these components to meet the requirements of the individual standard. Programs for automating EMC test procedures support setting up, calibrating, running, and documenting the complex and wide-ranging measurements required for EMC compliance test.